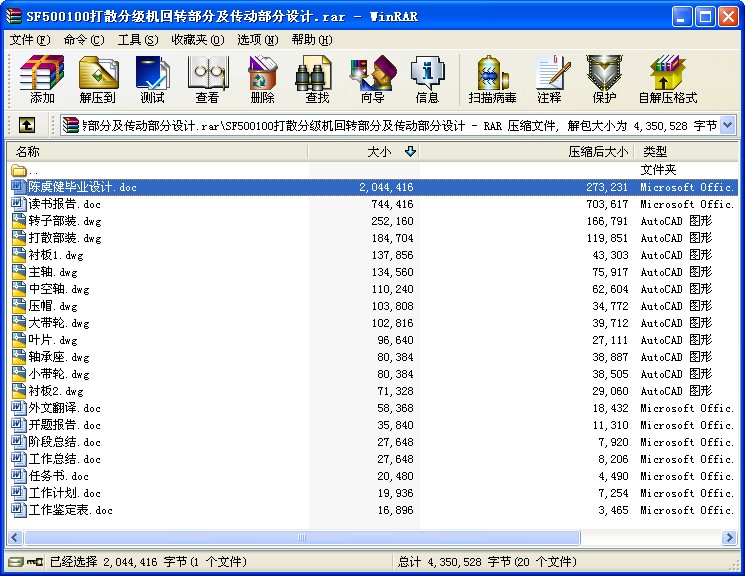

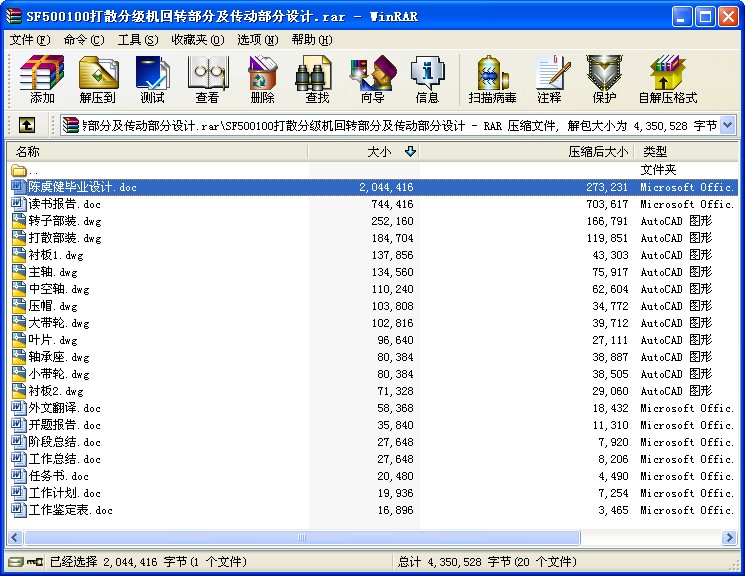

SF500100打散分級(jí)機(jī)回轉(zhuǎn)部分及傳動(dòng)部分設(shè)計(jì)

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- SF500100打散分級(jí)機(jī)回轉(zhuǎn)部分及傳動(dòng)部分設(shè)計(jì)

摘要

打散分級(jí)機(jī)是九十年代初問世的新型料餅打散分選設(shè)備,集料餅打散與顆粒分級(jí)于一體,與擠壓機(jī)配套使用,可以消除擠壓粉碎機(jī)邊緣漏料和開停機(jī)過程中及正常工作時(shí)未被充分?jǐn)D壓的大顆粒對(duì)后續(xù)球磨系統(tǒng)產(chǎn)生不利的影響,以獲得大幅度增產(chǎn)節(jié)能的效果。打散分級(jí)機(jī)利用離心沖擊破碎原理對(duì)物料進(jìn)行打散,利用慣性及空氣動(dòng)力學(xué)原理對(duì)散狀物料實(shí)現(xiàn)分級(jí)。

為了提高擠壓預(yù)粉磨工藝系統(tǒng)的產(chǎn)量,將更多的粉磨功移至磨外由擠壓打散回路承擔(dān),提高入磨物料的粒度和易磨性,本課題設(shè)計(jì)了水泥粉磨系統(tǒng)中擠壓磨后續(xù)設(shè)備打散分級(jí)機(jī)。整臺(tái)打散分級(jí)機(jī)采用整體緊湊設(shè)計(jì)的方法,降低了占據(jù)空間,且提高了打散和分級(jí)的效率。根據(jù)打散分級(jí)機(jī)的工作要求,采用工序高度集中的原則,確定了打散分級(jí)機(jī)的整體傳動(dòng)方案,應(yīng)用最優(yōu)化的方法設(shè)置了打散盤及風(fēng)輪的轉(zhuǎn)速,分析計(jì)算了系統(tǒng)的運(yùn)動(dòng)和動(dòng)力參數(shù)確定了傳動(dòng)比。進(jìn)行了電動(dòng)機(jī)的選擇、帶輪的設(shè)計(jì)、軸的結(jié)構(gòu)設(shè)計(jì)、軸的強(qiáng)度校核、鍵連接的選擇計(jì)算、滾動(dòng)軸承的類型代號(hào)選擇、軸承的壽命計(jì)算、聯(lián)軸器的選擇計(jì)算。在此方案的基礎(chǔ)上還進(jìn)行了改進(jìn)設(shè)計(jì),將雙傳動(dòng)拆開,這樣優(yōu)化了軸的設(shè)計(jì),提高了系統(tǒng)的穩(wěn)定性。

關(guān)鍵詞:輥壓機(jī);擠壓粉磨工藝系統(tǒng);打散分級(jí)機(jī);

The design of the rotary body and the transmission part of SF500/100 Scatter grading device

Student: CHEN Yu-jian Teacher: QIN Jian-hua

Abstract: Scatter grading device is the new blank cake which is published at the beginning of the 90's hits the divergence to choose the equipment, the aggregate cake to scatter with the size grading in a body, with the extruder necessary use, it may eliminate the disadvantageous influence extrusion grinder edge funnel and opens in when the engine off process and the normal work the big pellet which fully extrudes to the following grinding system has not been produced, which obtains the effect of the large scale production increase energy conservation. Scatter grading device carry on using the centrifugal impact crash principle to the material scatters, to disperse the shape realization graduation using the inertia and the aerodynamics principle.

In order to improve the grinding process system extrusion production, will more grinding work moved to the ground by extrusion scattered for loop, improve the grain size and material into the grinding mill sex, the subject of cement griding system design in grinding follow-up equipments scattered extrusion sorting machine. The whole machine by whole grade machine scattered compact design method, reduce the occupy space, and improve the efficiency of the scattered and classification. According to the classification of the machine work requires scattered, the process of the high concentration of principle, determined the classification of the whole machine scattered transmission scheme, the application of optimization methods set the speed of the rotor disc and scattered, calculating the system of sport and dynamic parameters determined the transmission. The choice of the motor, with the design of the shaft, wheel shaft structure design, the intensity, key link choice calculation, rolling bearing type selection, bearing life code calculation, the choice of the coupling calculation. On the basis of this project was the design improvement, will double drive apart, so the design of optimized shaft, improve the stability of the system.

Key words: Roller press; Compressed grinding system; Scatter grading device;

目 次

摘要 I

Abstract. II

第1章 緒論 1

1.1 前言 1

1.2 選題背景及意義 1

1.3 此次設(shè)計(jì)研究的主要內(nèi)容應(yīng)解決的問題 1

第2章 總體方案論證 2

2.1 設(shè)計(jì)方案的分析 2

2.2 打散分級(jí)機(jī)的工作原理 2

2.3 打散分級(jí)機(jī)的結(jié)構(gòu)分析 3

2.4 轉(zhuǎn)子部分分析 5

2.4.1 回轉(zhuǎn)部分分析 5

2.4.2 傳動(dòng)部分分析 6

2.5 方案二 6

第3章 打散部分設(shè)計(jì) 7

3.1 電動(dòng)機(jī)的選擇 7

3.2 帶輪的設(shè)計(jì)計(jì)算 7

3.3 軸的設(shè)計(jì)與強(qiáng)度校核 9

3.3.1 確定輸出軸運(yùn)動(dòng)和動(dòng)力參數(shù) 9

3.3.2 軸的結(jié)構(gòu)設(shè)計(jì) 10

3.3.3 軸的受力分析與計(jì)算 12

3.3.4 精確校核軸的疲勞強(qiáng)度 13

3.3.5 軸的靜強(qiáng)度校核 17

3.4 滾動(dòng)軸承的壽命計(jì)算 17

第4章 分級(jí)部分設(shè)計(jì) 19

4.1 電動(dòng)機(jī)的選擇 19

4.2 軸的設(shè)計(jì) 19

4.2.1 選擇軸的材料 19

4.2.2 確定輸出軸運(yùn)動(dòng)和動(dòng)力參數(shù) 19

4.2.3 軸的結(jié)構(gòu)設(shè)計(jì) 20

第5章 風(fēng)輪的結(jié)構(gòu)設(shè)計(jì) 23

第6章 結(jié)論 25

致謝 26

參考文獻(xiàn) 27

附錄 28 ...