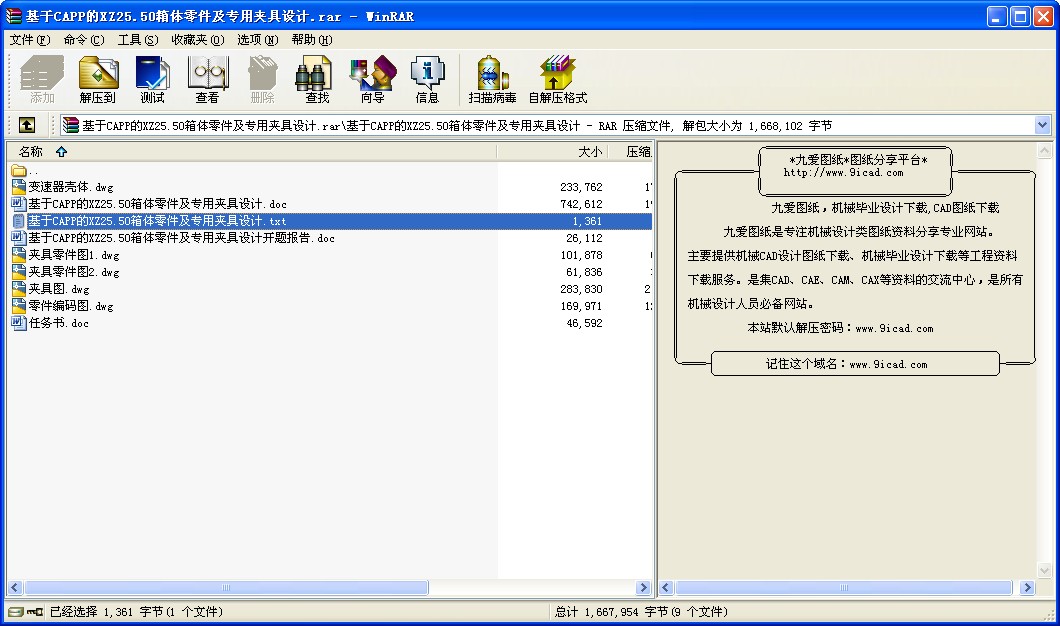

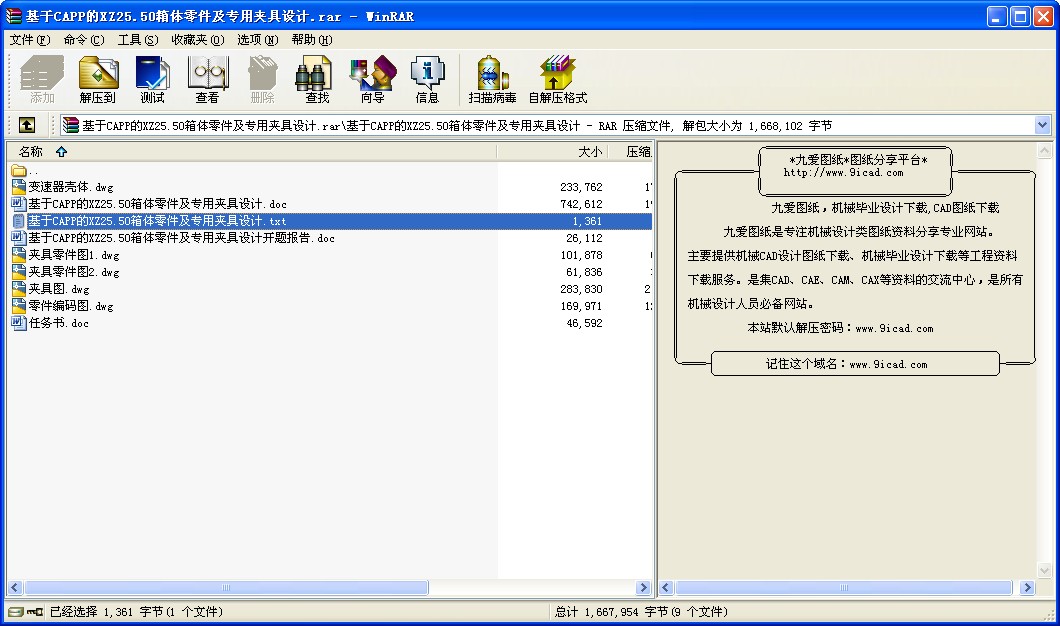

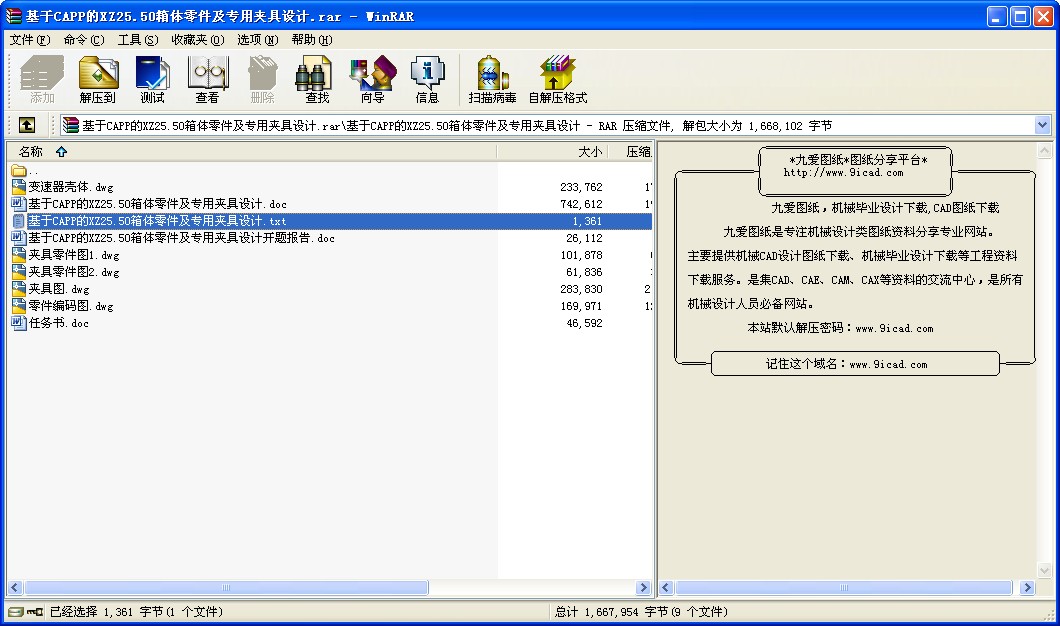

ª˘”⁄CAPPµƒXZ25.50œ‰Ûw¡„º˛º∞壔√äAæþ‘O(sh®®)”ã

- Œƒº˛ΩÈΩB£∫

- ‘쌃º˛ûÈ rar ∏Ò Ω£®‘¥Œƒº˛ø…æéð㣩£¨œ¬ðd–Ë“™

20 ∑e∑÷

-

- ª˘”⁄CAPPµƒXZ25.50œ‰Ûw¡„º˛º∞壔√äAæþ‘O(sh®®)”ã

1.ÆÖòI(y®®)‘O(sh®®)”㵃±≥æ∞£∫

CAPP(Computer Aided Process Planning£¨÷–Œƒ“‚Àº «”ãÀ„ôC(j®©)ðo÷˙π§

Àá“é(gu®©)Ñù) «Õ®þ^œÚ”ãÀ„ôC(j®©)ðî»Î±ªº”π§¡„º˛µƒ‘≠ ºîµ(sh®¥)ì˛(j®¥)£¨º”π§ólº˛∫Õº”𧓙

«Û£¨”…”ãÀ„ôC(j®©)◊‘Ñ”µÿþM(j®¨n)––æé¥a£¨æé≥Ã÷±÷¡◊Ó∫Ûðî≥ˆΩõ(j®©ng)þ^Éû(y®≠u)ªØµƒπ§Àá“é(gu®©)≥Ãø®

∆¨µƒþ^≥ð£

”ãÀ„ôC(j®©)¿˚”√”ãÀ„ôC(j®©)ÅÌþM(j®¨n)––¡„º˛º”π§π§Àáþ^≥õƒ÷∆”Ü£¨∞—√´ðo÷˙π§Àá“é(gu®©)

Ñù≈˜º”π§≥…π§≥ÃàDºà…œÀ˘“™«Ûµƒ¡„º˛£¨þ@“ªþ^≥Ã∑QûÈ”ãÀ„ôC(j®©)ðo÷˙π§Àá“é(gu®©)Ñù

À¸ «Õ®þ^œÚ”ãÀ„ôC(j®©)ðî»Î±ªº”π§¡„º˛µƒé◊∫Œ–≈œ¢£®–ŒÝÓ°¢≥þ¥Áµ»£©∫Õπ§Àá–≈

œ¢£®≤ƒ¡œ°¢ü·Ãé¿Ì°¢≈˙¡øµ»£©£¨”…”ãÀ„ôC(j®©)◊‘Ñ”ðî≥ˆ¡„º˛µƒπ§Àá¬∑æÄ∫Õπ§–Ú

É»(n®®i)»ðµ»π§Àጃº˛µƒþ^≥ð£

”ãÀ„ôC(j®©)ðo÷˙π§Àá“é(gu®©)ÑùµƒÉ»(n®®i)»ð÷˜“™”–£∫

¢ŸÆa(ch®£n)∆∑¡„º˛–≈œ¢ðî»Î£ª¢⁄√´≈˜þxìÒº∞√´≈˜àD…˙≥…£ª¢€∂®ŒªäAæo∑Ω∞∏þxìÒ£ª

¢Ðº”π§∑Ω∑®þxìÒ£ª¢ðº”π§Ìò–Ú∞≤≈≈£ª¢Þº”π§‘O(sh®®)lj∫Õπ§Àá—blj¥_∂®£ª¢þπ§Àá

Ö¢îµ(sh®¥)”ãÀ„£ª¢ýπ§Àá–≈œ¢£®Œƒº˛£©ðî≥ˆ°£

2.ÆÖòI(y®®)‘O(sh®®)”ã(’쌃)µƒÉ»(n®®i)»ð∫Õ“™«Û£∫

É»(n®®i)»ð£∫∏˘ì˛(j®¥)◊ÉÀŸœ‰œ‰ÛwµƒΩY(ji®¶)òã(g®∞u)Ãÿ¸c£¨‘⁄þM(j®¨n)––≥‰∑÷’ì◊Cµƒª˘µA(ch®≥)…œ÷∆∂®œ‰Ûwµƒ

º”π§π§Àá¬∑æÄ£¨”ãÀ„∏˜π§–ÚÖ¢îµ(sh®¥)£¨ÃÓå뺔π§π§Àáþ^≥㨑O(sh®®)”ã·ò嶑윉Ûw„ä

º”π§π§–Úµƒå£”√äAæþ°£≤¢å¶œ‰Ûw¡„º˛þM(j®¨n)––∑÷Óêæé¥a°£

1£Æ·ò嶜‰ÛwÓê¡„º˛µƒÃÿ¸cº∞…˙Æa(ch®£n)æVÓI(l®´ng)∫œ¿Ìæé÷∆¡„º˛π§Àá“é(gu®©)≥ãª

2£Æ’ì ˆCAPPµƒåç¨F(xi®§n)∑Ω∑®£¨ÕÍ≥…CAPPµƒåç¨F(xi®§n)∑Ω∑®£ª

3£Ææé÷∆¡„º˛µƒæé¥aœµΩy(t®Øng)£ª

4£ÆÕÍ≥…壔√äAæþµƒ‘O(sh®®)”ãøÇàDº∞¡„º˛àD£ª

5£ÆÕÍ≥…∂˛»f◊÷µƒÆÖòI(y®®)’쌃º∞5000◊÷µƒ◊gŒƒ°£

’™“™

þ@¥ŒŒ“ÆÖòI(y®®)‘O(sh®®)”㵃’nÓ}æÕ «ª˘”⁄CAPPµƒœ‰Ûwº”π§π§Àáº∞壔√äAæþ‘O(sh®®)”ã°£œ»·ò嶜‰Ûw¡„º˛µƒÃÿ¸c‘O(sh®®)”ãπ§Àá“é(gu®©)≥㨑Ÿ‘O(sh®®)”ã壔√äAæþ£¨◊Ó∫Û嶜‰Ûw¡„º˛þM(j®¨n)––∑÷Óêæé¥a°£

CAPP «Õ®þ^œÚ”ãÀ„ôC(j®©)ðî»Î±ªº”π§¡„º˛µƒ‘≠ ºîµ(sh®¥)ì˛(j®¥)£¨º”π§ólº˛∫Õº”𧓙«Û£¨”…”ãÀ„ôC(j®©)◊‘Ñ”µÿþM(j®¨n)––æé¥a£¨æé≥Ã÷±÷¡◊Ó∫Ûðî≥ˆΩõ(j®©ng)þ^Éû(y®≠u)ªØµƒπ§Àá“é(gu®©)≥Ãø®∆¨µƒþ^≥ð£”ãÀ„ôC(j®©)ðo÷˙π§Àá“é(gu®©)Ñù≥£ «¬ì(li®¢n)ΩY(ji®¶)”ãÀ„ôC(j®©)ðo÷˙‘O(sh®®)”ã(CAD)∫Õ”ãÀ„ôC(j®©)ðo÷˙÷∆‘Ï(CAM)µƒòÚ¡∫°£

‘⁄÷∆‘ÏòI(y®®)–≈œ¢ªØ≠h(hu®¢n)æ≥÷–£¨π§Àá‘O(sh®®)”ã «…˙Æa(ch®£n)ºº–g(sh®¥)ú (zh®≥n)ljπ§◊˜µƒµ⁄“ª≤Ω£¨π§Àá“é(gu®©)≥à «þM(j®¨n)––π§—b‘O(sh®®)”ã÷∆‘Ï∫ÕõQ∂®¡„º˛º”π§∑Ω∑®≈cº”π§¬∑æĵƒ÷˜“™“¿ì˛(j®¥)£¨À¸å¶ΩMøó…˙Æa(ch®£n)°¢±£◊CÆa(ch®£n)∆∑Ÿ|(zh®¨)¡ø°¢Ã·∏þÑ⁄Ñ”…˙Æa(ch®£n)¬ °¢ΩµµÕ≥…±æ°¢øs∂Ã…˙Æa(ch®£n)÷Ð∆⁄º∞∏ƒ…∆Ñ⁄Ñ”ólº˛µ»∂º”–÷±Ω”µƒ”∞Ì루 «…˙Æa(ch®£n)÷–µƒÍP(gu®°n)ÊIπ§◊˜°£π§Àá÷™◊R «÷∆‘Ï∆ÛòI(y®®)÷–÷ÿ“™µƒ÷™◊RŸY‘¥÷Æ“ª£¨ « πÆa(ch®£n)∆∑‘O(sh®®)”ã◊É?y®≠u)È≥…∆∑µƒ’˚ÇÄ÷∆‘Ïþ^≥Ã÷–µƒª˘µA(ch®≥)ŸY‘¥£¨À¸å¶±£◊CÆa(ch®£n)∆∑Ÿ|(zh®¨)¡ø“‘º∞÷∏þ∆ÛòI(y®®)Ωõ(j®©ng)ù˙(j®¨)ºº–g(sh®¥)–ß“Êæþ”– Æ∑÷÷ÿ“™µƒ◊˜”√°£

äAæþµƒøÏÀŸ‘O(sh®®)”ã≈c÷∆‘Ï£¨º∫Ωõ(j®©ng)≥…ûÈÆa(ch®£n)∆∑øÏÀŸ◊ÉìQ∫Õ÷∆‘ÏœµΩy(t®Øng)–¬Ω®≥…ªÚ÷ÿòã(g®∞u)∫Ûþ\(y®¥n)––µƒ∆øÓi£¨á¿(y®¢n)÷ÿµÿ”∞Ìë÷∆‘ÏœµΩy(t®Øng)µƒ‘O(sh®®)”ãΩ®‘Ï÷Ð∆⁄°¢œµΩy(t®Øng)…˙Æa(ch®£n)¬ °¢Ÿ|(zh®¨)¡ø∫Õ≥…±æ°£å£”√äAæþµƒ π”√£¨“ª∑Ω√Êøs∂áÀπ§–ÚïrÈg£¨ΩµµÕ¡Àº”π§≥…±æ£ª¡Ì“ª∑Ω√Ê£¨äAæþ±æ…̵ƒ‘O(sh®®)”ã÷∆‘Ïπ§ïr°¢≤ƒ¡œœ˚∫ƒµ»”÷‘ˆº”¡Àπ§º˛µƒ≥…±æ°£“Ú¥À£¨‘⁄∫Œ∑N…˙Æa(ch®£n)ólº˛œ¬ π”√ƒƒ∑NÓê–ÕµƒäAæþ≤≈ «Ωõ(j®©ng)ù˙(j®¨)∫œ¿Ìµƒ£¨“≤æÕ «äAæþµƒΩõ(j®©ng)ù˙(j®¨)–‘£¨“ª÷±∂º «äAæþΩY(ji®¶)òã(g®∞u)∞l(f®°)’π∫Õ‘O(sh®®)”㵃“ªÇÄ÷˜“™ÜñÓ}°£

ÍP(gu®°n)ÊI‘~:CAPP£ªπ§Àá‘O(sh®®)”㣪壔√äAæþ

Abstract

This my Graduation Design is based on the CAPP XZ25.50 box of technological procedure and Special fixture design. First direcated against the peculiarity of the parts case design technological procedure,and design the special fixture, finally classification coding parts box.

CAPP, through the importation of computer parts were processing the raw data, processing conditions and processing requirements, carried out automatically by computer coding, programming optimized output until the end of the process of order card process. Computer-aided process planning is often linked computer-aided design (CAD) and computer-aided manufacturing (CAM) as a bridge.

The manufacturing industry becoming an information based society environment, the process planning produces is the first step in the technology preparatory work, the process planning is carries on the work clothes design to make and to decide the components processing method with processes the route the main basis, it produces, guarantee product quality, the enhancement labor productivity to the organization, reduces the cost, reduces the production cycle and the improvement work condition and so on all has the direct influence, is in the production key work. The craft knowledge is makes in the enterprise one of important knowledge resources, is causes the product design to become the end product in the entire manufacture process foundation resources, it to guaranteed the product quality as well as enhances the enterprise economical technology benefit to have the extremely vital role.

The fast design and the manufacture, oneself after becomes the product fast transformation and the manufacture system completes the bottleneck newly which or the heavy construction moves, seriously affects manufacture system the design construction cycle, the system productivity, the quality and the cost. Unit clamp use, on the one hand reduced the working procedure time, reduced the processing cost; On the other hand, the jig itself design manufacture man-hour, the material consumption and so on increased the work piece cost. Therefore, which kind of type uses under what kind of working condition the jig is the economy reasonable, also is the jig efficiency, continuously all is the jig structure development and a design main question.

Keywords CAPP Process Design Special Fixtur

ƒø ‰õ

1æw’ì 1

2 ¡„º˛º”π§π§Àá“é(gu®©)≥à 3

2.1∏≈ ˆ 3

2.2¡„º˛µƒ◊˜”√ 3

2.3 ¡„º˛µƒπ§Àá∑÷Œˆ 3

2.4¥_∂®π§Àá∑Ω∞∏µƒ‘≠Ñtº∞◊¢“‚ÜñÓ} 3

2.4.1¥÷°¢æ´º”π§∑÷È_‘≠Ñt 3

2.4.2π§–ÚºØ÷–≈c∑÷…¢µƒ‘≠Ñt 4

2.4.3÷∆∂®π§Àá∑Ω∞∏ë™(y®©ng)◊¢“‚µƒ∆‰À¸ÜñÓ} 5

2.5π§Àá“é(gu®©)≥õƒ‘O(sh®®)”ã 5

2.5.1¥_∂®√´≈˜≤ƒ¡œº∞≥þ¥Á 5

2.5.2∂®Œªª˘ú (zh®≥n)µƒþxìÒ 5

2.5.3÷∆∂®π§Àá¬∑æÄ 6

2.6π§–Ú≥þ¥Áµƒª˘±æ“™«Û 7

2.7 ¥_∂®«–œ˜”√¡ø∫Õª˘±æπ§ïr 8

2.8 «–œ˜”√¡øµƒþxìÒ“¿ì˛(j®¥) 22

2.8.1„䜘 22

2.8.2„@ø◊ 22

2.8.3îU(ku®∞)ø◊∫Õ„qø◊ 23

2.8.ôC(j®©)¥≤æ´∂»º∞ôC(j®©)¥≤Ö¢îµ(sh®¥) 23

2.9 ∏˜∑Nº”π§π§Àá∫Õº”π§∑Ω∑® 24

2.9.1∆Ω√ʺ”π§π§Àá 24

2.9.3¬ðºyº”π§π§Àá 24

2.10≥£”√π§Àá÷˜“™π§–ÚƒÐþ_(d®¢)µΩµƒæ´∂»∫Õ±Ì√Ê¥÷≤⁄∂» 24

2.10.1∆Ω√ʺ”π§ 24

2.10.2¬ðºyø◊º”π§ 25

3 壔√äAæþµƒ‘O(sh®®)”ã 26

3.1 嶄ä¥≤äAæþÛwµƒ“™«Û 26

3.2 äAæþÛwµƒ√´≈˜ΩY(ji®¶)òã(g®∞u) 26

3.3äAæþ‘™º˛µƒþxìÒ≈c‘O(sh®®)”ã 26

3.4 壔√äAæþµƒ‘O(sh®®)”ã≤ΩÛE 27

3.5 ¿L÷∆äAæþøÇ—b≈‰àD 27

3.6 òÀ(bi®°o)◊¢äAæþøÇ—b≈‰àD…œÇÄ≤ø∑÷≥þ¥Á∫Õºº–g(sh®¥)“™«Û°£ 28

3.7 äAæþπ´≤Ó≈‰∫œµƒ÷∆”Ü 28

3.7.1 ÷∆”ÜäAæþπ´≤Ó≈cºº–g(sh®¥)ólº˛µƒ“¿ì˛(j®¥) 28

3.7.2 ÷∆∂®äAæþπ´≤Ó∫Õºº–g(sh®¥)ólº˛µƒª˘±æ‘≠Ñt 28

3.8äAæþπ´≤Óµƒ÷∆”Ü 29

3.9 äAæþºº–g(sh®¥)ólº˛µƒ÷∆”Ü 29

3.10äAæþ‘O(sh®®)”ã≤ø∑÷µƒ”ãÀ„ 29

3.10.1ª˘ú (zh®≥n)µƒþxìÒ 29

3.10.2«–œ˜äAæo¡¶µƒ”ãÀ„ 29

3.10.3∂®Œª’`≤Óµƒ∑÷Œˆ 30

4 ¡„º˛æé¥aœµΩy(t®Øng) 33

4.1¡„º˛æé¥aœµΩy(t®Øng)µƒ∏≈ƒÓ 33

4.2¡„º˛∑÷Óêæé¥aœµΩy(t®Øng)µƒ“™«Û 34

4.3¡„º˛∑÷Óêæé¥aœµΩy(t®Øng)µƒ‘O(sh®®)”ã∫ÕþxìÒ 34

4.4¡„º˛µƒ∑÷Óê≥…ΩMºº–g(sh®¥) 34

4.4.1æé¥a∑÷Óê∑® 34

4.4.2…˙Æa(ch®£n)¡˜≥Ã∑÷Œˆ∑® 35

øÇΩY(ji®¶) 38

÷¬÷x 39

Ö¢øºŒƒ´I(xi®§n) 40

∏Ω‰õ 41

...

ø¥≤ª«Â≥˛,ìQ“ªÇÄ

ø¥≤ª«Â≥˛,ìQ“ªÇÄ

ü·ÈTÍP(gu®°n)ÊI‘~£∫

ü·ÈTÍP(gu®°n)ÊI‘~£∫

‘•π´æW(w®£ng)∞≤lj 41072402000322Ãñ

‘•π´æW(w®£ng)∞≤lj 41072402000322Ãñ